On leather work

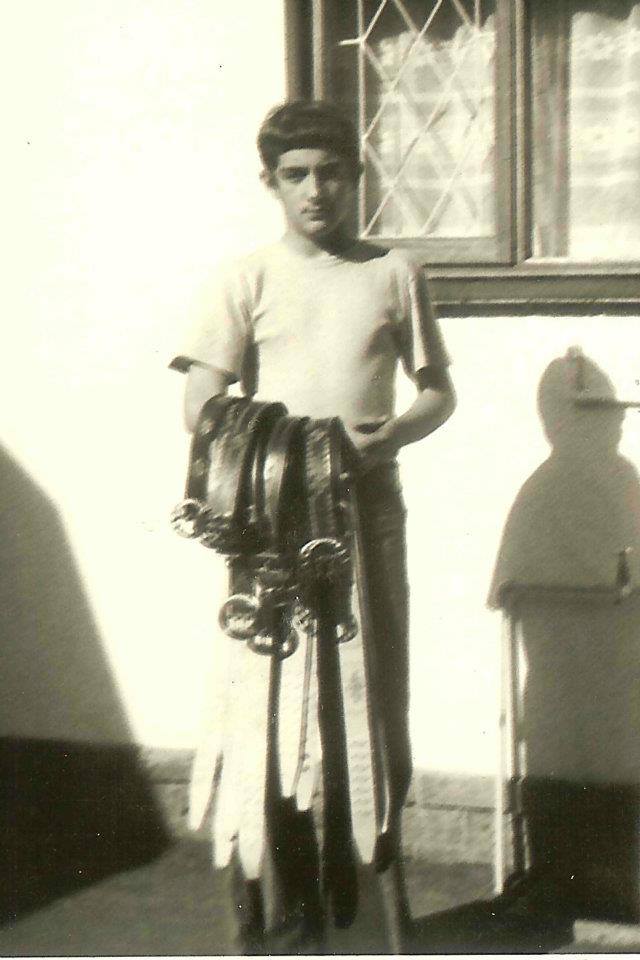

Yesteryear. Back in Std. 9, as a 14 year old, Levi 501 jeans were in fashion, worn with a T-shirt that had baggy sleeves and a decent pair of Bongola boots – the light grey ankle boots with off-white rubber soles. Or even better – fireman boots but other than Clive Deacon and myself, few guys knew where to purchase them. You also needed a thick leather belt, around 2 inches wide with a large buckle, and one with designs on it. Such belts were rather expensive and few Woodlands boys could afford them.

I took the Woodlands 210 bus to downtown Durban, walked down Field Street across Pine Street and into Commercial Road where I visited AC Smith Saddlery, a horsey-type shop that belonged to Mr. Smith, the father of Titch Smith and his brother, two good cricket players in the day.

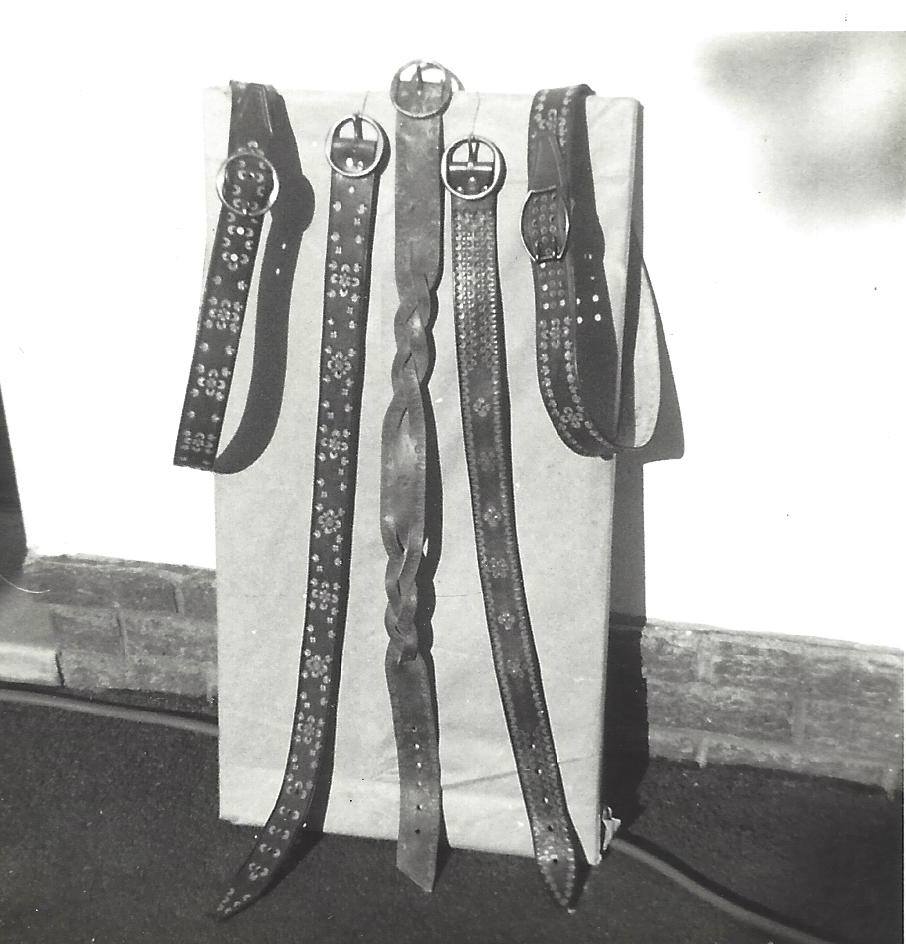

They sold raw cow hides as well as leather strips for belts. You chose the width of the piece of leather you wanted, either from Edgar or Sydney, who would cut a strip off, bought some dye, a few studs and a buckle and you had all of the ingredients for a leather belt. You had to do a bit of thinking and homework – there was no Google or YouTube on how to make a belt.

My first attempt was a little crude but not bad at all. I wet the leather and punched a few designs into it with a round punch and a flat screwdriver. Clive saw the belt and was most impressed – he needed one! And so I made the second one but his time I got a little fancier. I took a bolt and filed some designs onto it, made a few small holes with a metal punch and ended up with something that resembled a flower. The next punch was even better – I cut the top of a bolt off, ended up with a round piece of metal and with a round file I filed away from the side, leaving a half moon design that I decorated by knocking little holes into it with a metal punch.

Within a few days I had some requests for a few more belts and the 210 bus rides happened more and more and I quickly befriended Sydney and Edgar. Once they had cut a strip of leather off they had to weigh it and you paid per weight. The more you purchased, the more lenient they were with the weight and the less you paid.

In no time at all it became a lucrative business and I was finding it more and more difficult to fit school in. I could basically make a leather belt for R2.00 and easily sell it for R3.00 and on Saturday, if I started at 06:00 with LM Radio blaring in the background, I could finish 90 belts. For some perspective, a good second-hand 50 cc motorbike cost around R100.00 in those days.

I also started making leather handbags and then moved onto sandals – the ones with a piece of leather that fitted over your big toe and a broad leather strap over the bridge of your foot. I made more and more stamps, even creating my own Hang Ten feet!

Business was booming, a little bit of homework in the background and within months I was supplying some if the Indian clothing stores in Clairwood (Dominion, Kajee’s Cycle Works and a few others) with leather belts and some were even exported to the UK. Another nice break was when Bata shoes approached me to design some sandals for them.

My little business was growing very nicely and I could count up to a dozen people wearing my belts if I visited downtown Durban on a Saturday. But then I bought my first Suzuki AS 50 motorbike and before I knew it I had a far more profitable business in motorbikes. But more of that later.